How Outsourced Quality Inspection Solutions Support High-Growth Manufacturing

In the high-stakes world of automotive and aerospace manufacturing, scaling up production is a double-edged sword. While increased orders signify growth, they also place immense pressure on quality management systems. As line speeds increase and new shifts are added, the risk of a quality escape rises exponentially.

This is where third-party quality inspection solutions become a strategic asset for growing manufacturers.

The Challenge of Rapid Scaling

When a facility transitions from low-volume production to full-scale manufacturing, several “quality friction points” typically emerge:

Training Gaps: New hires may not have the refined “eye” for defects that veteran operators possess.

Fatigue Factors: Increased overtime and back-to-back shifts can lead to human error during the inspection phase.

Resource Dilution: Quality managers often find themselves buried in paperwork rather than walking the floor to monitor processes.

How Third-Party Inspection Eases the Transition

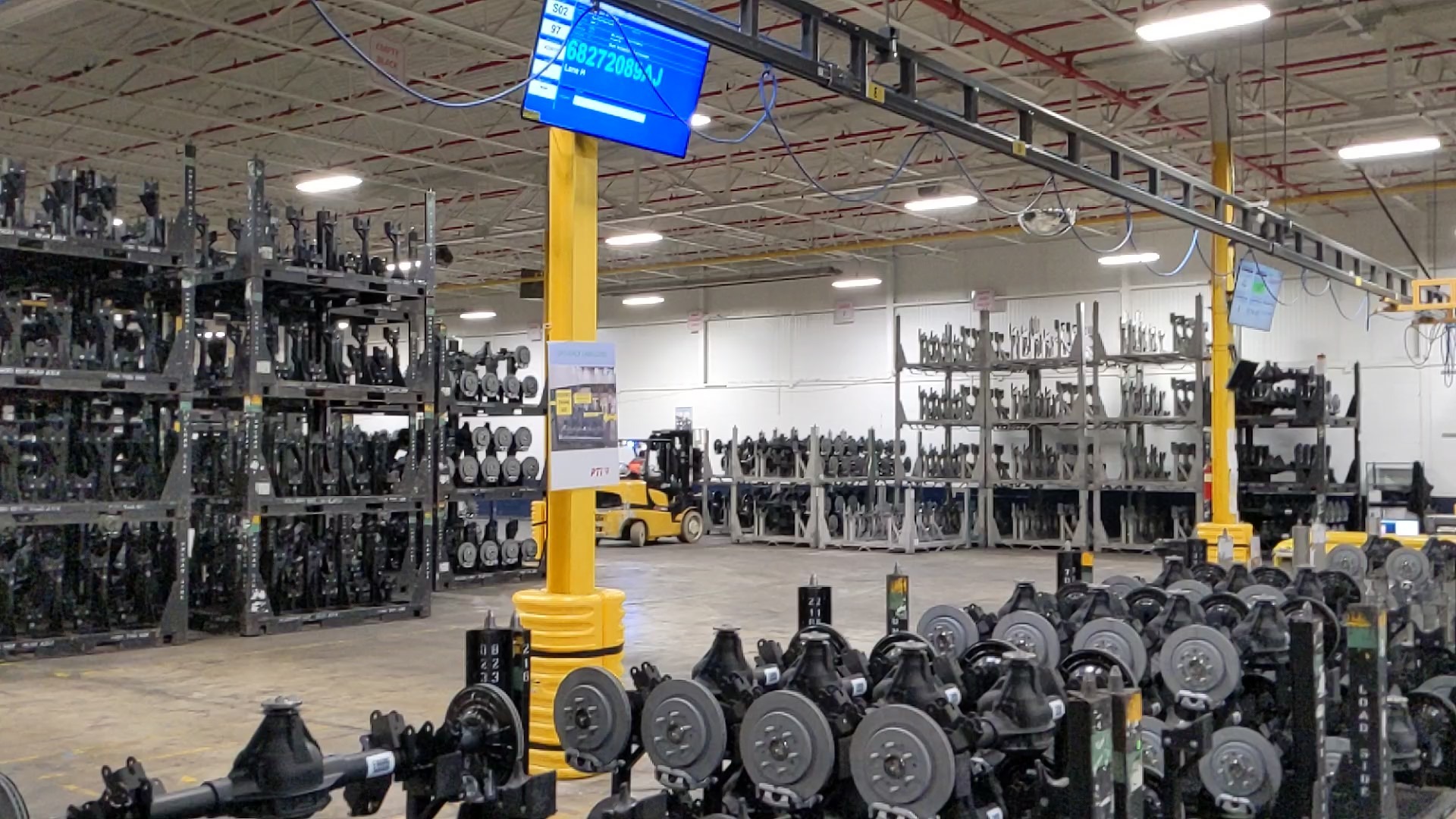

By integrating a third-party inspection team into your scaling strategy, you create a dedicated layer of defense that operates independently of production pressures.

Unbiased Verification Third-party inspectors have one goal: to ensure every part meets the documented specifications. Unlike internal production teams, they are not motivated by “hits per hour,” which ensures that quality never takes a backseat to volume.

Specialized Expertise and Tools A professional inspection partner brings a toolkit that might not yet be available in-house. From specialized borescapes to high-precision measurement technology, they provide the technical depth required to validate complex geometries at high speeds.

Flexibility in Workforce Management Demand in the automotive sector can be volatile. Third-party providers allow you to flex your inspection headcount up or down based on current shipping requirements, protecting you from the overhead of permanent hires during temporary surges.

Bridging the Gap to the OEM

Perhaps the greatest benefit of third-party quality inspection is the confidence it instills in your customers. When an OEM knows that a dedicated, professional inspection firm is validating your output, it reduces the likelihood of disruptive audits and builds a foundation of trust that is essential for long-term contract retention.

Conclusion

Scaling production is a milestone for any manufacturer, but it must be managed with precision. Partnering with a quality inspection specialist allows you to focus on the “how” of manufacturing while they focus on the “what” of quality excellence.

Contact Us Today:

Phone: (833) 784-9675

Address: 18615 Sherwood St, Michigan, 48234