The Financial and Operational Advantages of Third-Party Quality Containment Solutions

For Tier 1 and Tier 2 automotive suppliers, the discovery of a quality defect triggers a race against the clock. While the immediate instinct may be to use internal production staff to sort through suspect material, this approach often leads to hidden costs and secondary risks.

Partnering with an specialized automotive containment company allows your facility to remain focused on its core mission: manufacturing high-quality parts at scale.

The Hidden Costs of Internal Sorting

When you pull your own operators off the line to perform emergency sorting, you aren’t just paying for their hourly wage. You are incurring several “hidden” costs that can damage your bottom line:

Lost Opportunity Cost: Every hour an operator spends sorting is an hour they are not producing billable parts. This often leads to expensive overtime later in the week to meet production quotas.

Inherent Bias: Internal staff may feel pressured to “pass” parts to avoid looking bad or to meet shipping deadlines, increasing the risk of a secondary escape to the OEM.

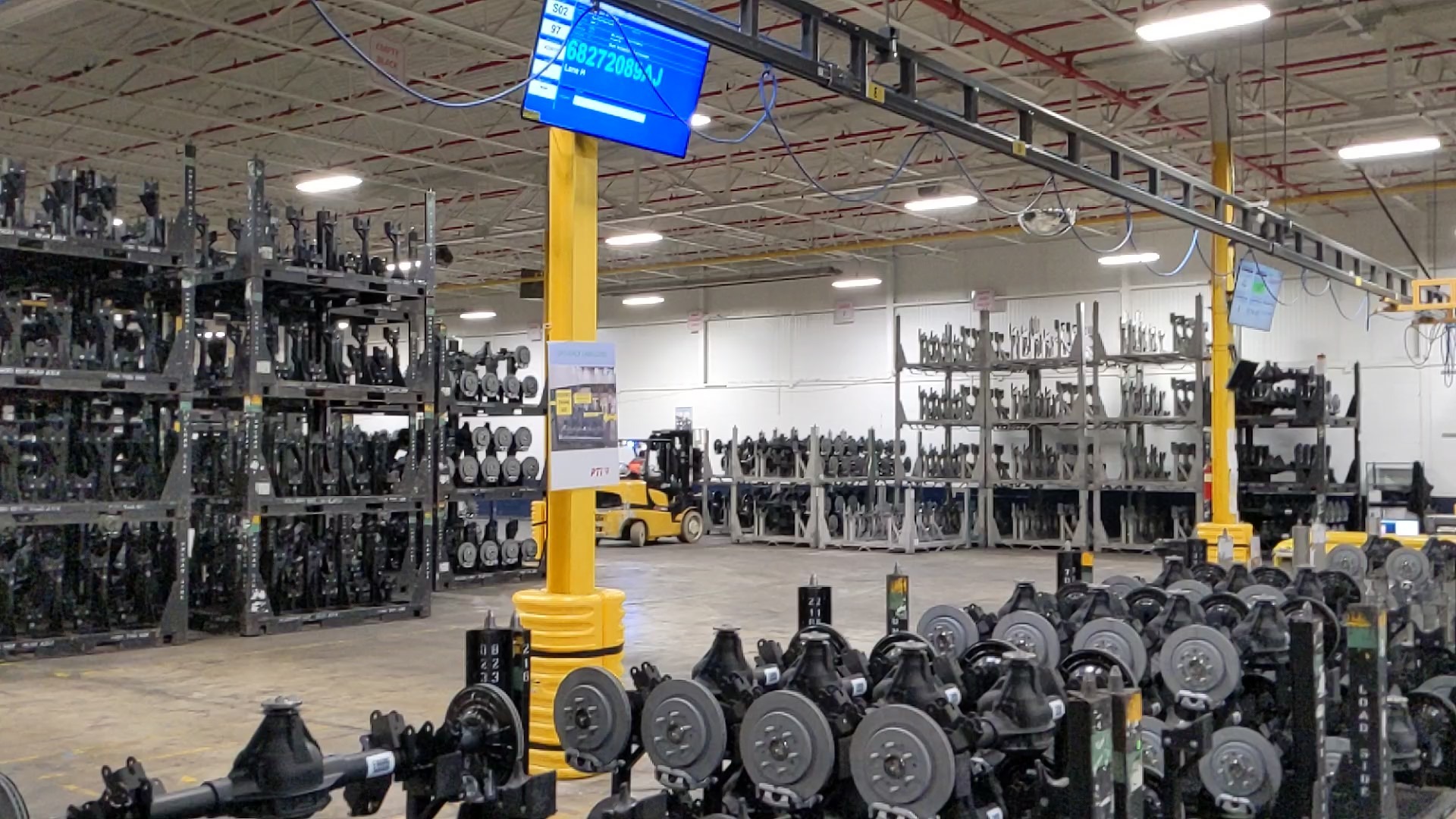

Lack of Specialized Equipment: Professional containment companies bring their own calibrated gauges, vision systems, and lighting arrays, ensuring a higher level of precision than a makeshift sorting station on a production floor.

The Strategic Value of Professional Containment Solutions

A professional containment process provides a “firewall” between your plant and your customer. By outsourcing this function, you gain several strategic advantages:

Immediate Scalability A quality escape might involve ten parts or ten thousand. A professional containment company can scale their workforce up or down instantly, ensuring that your containment plan is executed without creating a bottleneck in your logistics.

Standardized Data and Reporting Third-party providers use digital reporting systems to track defect trends in real-time. This data is essential for your engineering team to perform Root Cause Analysis (RCA) and implement permanent corrective actions.

Objective Certification When a third party certifies a lot as “Green,” it carries more weight with OEM quality managers. It demonstrates that you are taking the issue seriously and have implemented an unbiased verification layer.

Conclusion: Protecting Your Reputation and Your Profit

In the automotive industry, your reputation is your most valuable asset. Outsourcing to a professional containment company like PTI ensures that quality issues are handled with the highest level of transparency and technical expertise, allowing you to protect your OEM relationships and your operational efficiency.

Contact Us Today:

Phone: (833) 784-9675

Address: 18615 Sherwood St, Michigan, 48234