Pretreatment Capabilities

Advanced Surface Treatment Solutions by PTI QCS: Alkaline Cleaning, Iron & Zinc Phosphate Treatments

PTI QCS is committed to delivering top-notch surface treatment solutions, ensuring your materials are optimally prepared for further processing or use.

PTI QCS OFFERS ALKALINE CLEANING

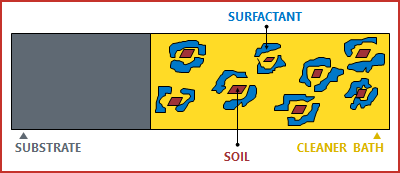

- Effective Contaminant Removal: This process expertly removes surface contaminants from parts, specializing in dealing with oily soils.

- Advanced Detergency: The products used boast exceptional detergency, effectively targeting greasy and oily surfaces.

- Enhanced Wetting and Emulsification: Our alkaline cleaning involves surfactants that enhance the wetting of oily surfaces, aiding in the emulsification and dispersion of oils and soils.

PTI QCS OFFERS IRON PHOSPHATE TREATMENT

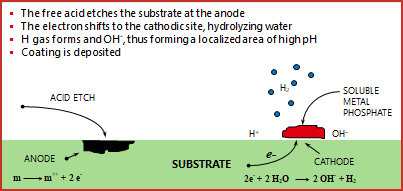

- Optimal for Multiple Surfaces: Ideal for treating Aluminum, iron, or steel surfaces before painting.

- Molecular Surface Transformation: This treatment causes a reaction that alters the molecular structure of the surface, significantly improving paint adhesion – up to 1,000 times better than untreated metal.

- Increased Durability: Iron phosphating enhances impact resistance and flexibility.

- Oxidation Prevention: Treated surfaces can prevent the progression of oxidation under the paint when impacted.

- Amorphous Coating Benefits: Also known as an amorphous coating, it provides a bondable surface and contains iron and phosphates without crystal formation.

PTI QCS OFFERS ZINC PHOSPHATE TREATMENT

- Crystalline Conversion Coating: Suitable for steel and other metals, forming a crystalline conversion coating on ferrous metal substrates.

Preparation for Coating or Painting: Employed as a pretreatment step to enhance corrosion protection and impact resistance.

Versatile Application: Useful for threaded parts and combined with oil (P&O) for anti-galling and rust inhibiting properties.

Tri-cationic Chemical Conversion: Alters both the chemical and physical nature of the metal surface, improving paint adhesion and corrosion protection.

Surface Replacement with Stable Minerals: This process replaces metal surfaces with a stable, non-metallic polycrystalline surface, integrating Zinc, Iron, Manganese, Nickel, and phosphates into the crystals.